Our group has a rich history in developing key technologies that have enabled the success of LIGO, including:

- Key components of the laser used in Initial LIGO

- Seismic isolation platform

- Silicate bonding

- Photo-thermal interferometer

The seismic isolation platform and silicate bonding in particular are key technologies that have been instrumental to the success of Advanced LIGO.

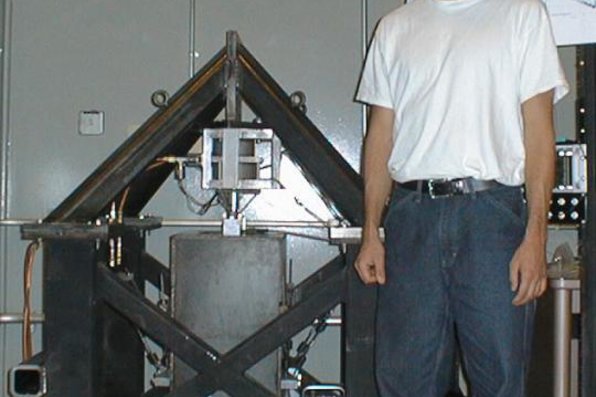

Seismic Isolation System

The team at Stanford have been leaders in the research and development of the Seismic Isolation system used to support the Advanced LIGO optics. The Suspension and Seismic Isolation systems used in Advanced LIGO are designed so that the motion of the optic at 10 Hz will be limited by thermally driven motion. However, at this frequency the motion of the ground is typically 9 or 10 orders of magnitude larger, so the seismic isolation of the optic is a great challenge. In addition, the optic must be controlled to keep the interferometer at its working point, even though (for example) the moon causes the 4 km interferometer arms to stretch by about 100 microns as the tidal bulges move past the detector.

The main optics are suspended by a 4 stage pendulum system designed by LSC parters in Scotland and the GEO project. The pendulum is supported by the Seismic Isolation System, which has a 2 stage hybrid active/ passive table in the vacuum system, and that table is supported by an in-air positioning system driven by laminar-flow quiet hydrualic actuators. Although this Hydraulic External Pre-Isolator (HEPI) was designed for Advanced LIGO, the LIGO team decided to install it as part of Initial LIGO at the Livingston site to help control the optics in that challenging seismic enviroment. This was voted one of the three key technology updates which enabled Initial LIGO to succeed.

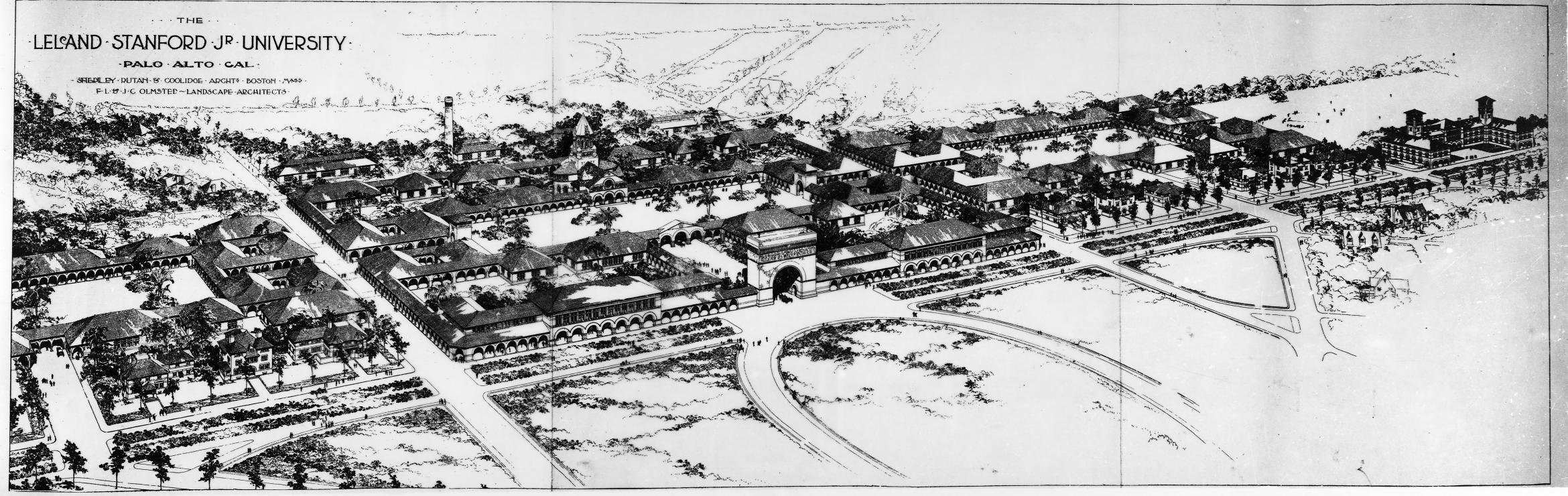

The two-stage hybrid active/ passive isolation system is an evolution of work which has been proceeding for several decades here at Stanford, as well as at JILA, Caltech, MIT, and recently at the LIGO observatories. The Ginzton and HEPL labs on campus have a long history of multi-disciplinary research, so it was easy for Prof. Robert Byer (Applied Physics) to join forces with Prof. Dan DeBra (Aero-Astro department, and by courtesy Mech E and the Design Division) who is an expert on Precision Engineering and automatic control and develop the concepts for the precision isolation and control required for the optical table for Advanced LIGO.

Photothermal Common-path Interferometry

The commercial use of nonlinear optical materials requires that properties other than nonlinear coefficients and birefringence be measured. These properties include absorption, surface and bulk damage limits, grey tracking and green induced infrared absorption. One of the most important properties is simple light absorption. In the early years of the field the absorption was large but as the materials improved and the absorption became smaller, more sensitive measurement techniques were needed.

When Advanced LIGO began development in the late 90s, it was clear that a close comparison between the properties of silica and sapphire for test mass substrates would require measurements techniques with much higher sensitivity. The absorption of the ion beam sputtered coatings in aLIGO would be in the sub-ppm region. Several different pump probe techniques were developed, but the best approach was the Photothermal Common-path Interferometry (PCI) developed at Stanford University by Alexander Alexanderovski.

In PCI a small high-power pump laser beam is used to illuminate a sample to be measured, and a second larger low-power probe is centered on the first beam. The thermo-optic distortions due to the heating of the sample by the pump beam produce a small lens-like distortion on the probe beam phase front and PCI measures this distortion with dual-beam interferometric sensitivity. In response to a broad interest in this approach, a company was incorporated, Stanford Photo-Thermal Solutions, (SPTS) to meet the needs of the optics community for industrial and research equipment for the measurement of surface and bulk absorptions, and also to provide services for the measurement of samples. Since its founding SPTS has had sold 30 complete measurement systems and has over 100 service customers in the optics and homeland security communities and is currently incorporated and operating in Hawaii.

Silicate Bonding

Jointing techniques with high mechanical strength and stability are required for use in the fabrication of optical systems used in space-based applications such as telescope assemblies and optical benches. The original technique of hydroxy-catalysis, or "silicate" bonding was invented and patented at Stanford University by Gwo for the purpose of jointing the fused silica pieces forming the star-tracking telescope assembly used in the Gravity Probe B space experiment. LIGO has used a variant of this technique to fabricate the quasi-monolithic fused silica suspensions now being installed for Advanced LIGO and previously used in the GEO 600 gravitational wave detector. This technique was selected for use in ground-based gravitational wave detectors because of its high strength with very thin bonding layers combined with low mechanical loss, thus maintaining low thermal noise.

The original technology has been transferred to a number of optical vendors. Development of Oxide-bonding techniques was supported by a PIPSS technology transfer award to SpanOptic Ltd (UK), with a patent granted for bonding silicon carbide (US2007/0221326 A1). In addition, further contracts and partnerships have been established in this area with Gooch and Housego (UK), HighYaG (Germany) and Calyxo (USA).

Materials

The broader impact of our materials research is not only limited to GW detectors as the atomic structure of the coatings is of great interest to the wider materials science community. The coating materials have many other applications, such as ring laser gyroscopes used in precision guidance systems, and optical atomic clocks. Therefore, anything we learn about the atomic structure of these coatings, and how this relates to material properties such as mechanical loss, will have a much broader impact. Also, the development of the experimental techniques used in this research can be used to study many different coating technologies and materials in a general sense, and so can have wide-ranging applications.